| Well here is the hardware just before installation.

Being that I didn't want to move the crank, water pump, and alternator

pulleys out I had to mount the wheel on the outside of the crank pulley.

I had to make three spacers to move the wheel out and the two longer ones

to reposition the pickup arm so that the sensor would be centered over

the wheel. |

|

| One step closer to putting them on the car. |

|

| Got the wheel mounted to the damper. Mounting it out

in space like this I lost the use of the centering rings. Here I

have the dial indicator setup adjusting run out. They spec'd +/-

.010". I got it down to +/- .002" run out. I got lucky here

as it pretty much centered up with just a few taps. Wasn't much fun

pulling the motor through by the flywheel while trying to monitor the indicator though.

You can really tell by this picture but it was not an easy task getting

the dial indicator in position. The magnetic base and arms zigzagged

back and forth several times to position the darn thing. Took longer

to mount it than to adjust the run out. |

|

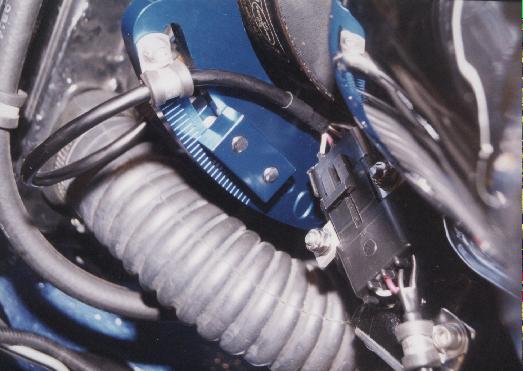

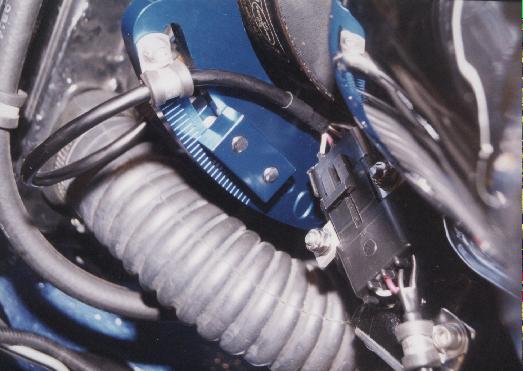

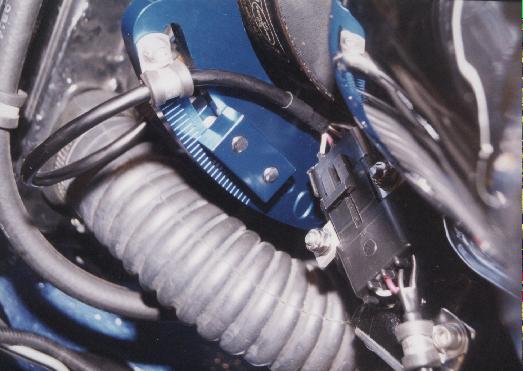

| You can see how close the pickup and the output lead came

to the lower radiator hose. I lucked out here because when they potted

the wire into the pickup housing they got it off center. Was able

to rotate the pickup for maximum clearance. Some of the strain relief's

and mounting of the connector can be seen also. I didn't want that

heavy connector flopping around in space. |

|

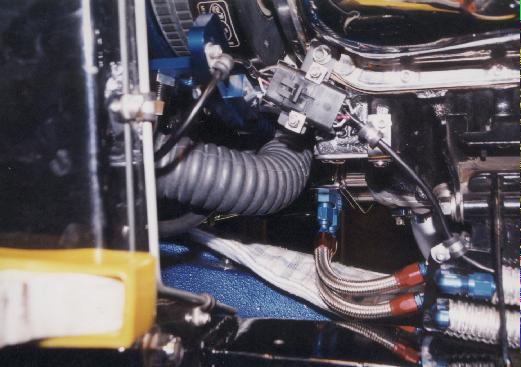

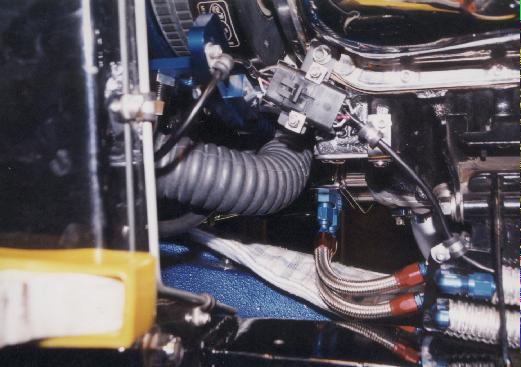

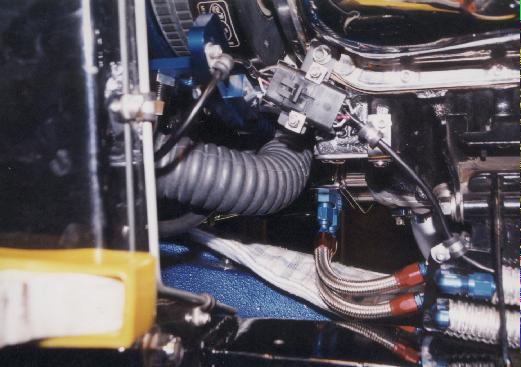

| A little different view of the final installation.

You can just see at the lower right side of the picture where I fished

the pickup cable under the fuel line heat insulation. That insulation

is quite a bit larger diameter than the 3/8" fuel plumbing, so tie-wrapping

it to the line and hiding it under the insulation got the wiring headed

in the right direction to the rear of the car and also protected from the

heat of the nearby headers. |

|