AMC Power has incorporated our unique flow-measuring

technology into a device designed specifically for measuring airflow into cyclone burners.

This schematic shows the typical configuration of ten-foot cyclones in a common windbox.

Because it would be difficult to test such a device on a furnace with

multiple cyclones in a common Windbox, we have utilized our test chamber, designed to AMCA

standards, in Santa Rosa, CA to test the product. The test chamber consists of a large

plenum (windbox) which houses a "mock-up" of a cyclone inlet (B&W drawings

were utilized to create the "mock-up"). We have simulated turbulent conditions

caused by obstructions in the windbox and by the cyclone itself. This was accomplished by

modulating the split dampers on the exhaust and by utilizing a variety of obstructions at

the cyclone inlet to replicate actual windbox conditions. We have tested this

flow-measuring device through the same velocity (flow) range that the cyclone would

experience in service. The results have proven the product we have developed can be used

to accurately/repeatably measure flow to each cyclone. The end result will be that it can

be used to balance airflow to each cyclone in a furnace, and thus lead to increased

furnace performance and decreased NOx levels. Another immediate benefit is the inlet

screens (bells) can be removed which will allow for the removal of as much as 12

IN.. w.c.

of permanent pressure drop in the system. This will yield more fan capacity, which should

prevent the need for rework or replacement due to FD-limited situations. In addition to

secondary airflow, we are also building flow stations for the primary/tertiary inlets to a

cyclone burner for evaluation.

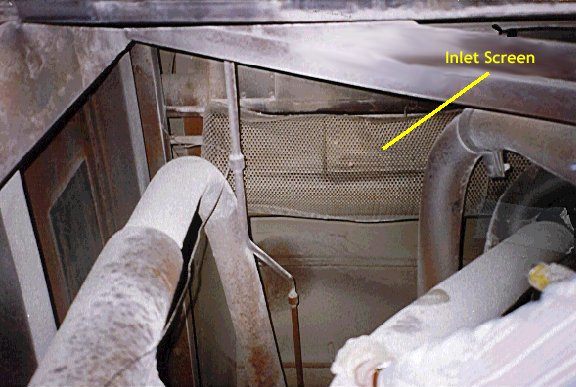

Not only are the inlet screens a tremendous waste of fan energy, they

are also an ineffective way of measuring flow. These systems were designed to be

calibrated using a Pitot tube. Inserting a Pitot tube in such a turbulent environment has

proven to be a futile way of calibration. In addition, inlet screens can be damaged over

time as shown here, resulting in major altering of initial calibration coefficients.

Removal of the screens and installing AMC Power Combustion Airflow Stations will result in more accurate

information that can be used to optimize boiler performance. Not only can this information

be used to increase efficiency through burner balancing, it can also be used to bias

burners for achieving lower NOx.

Our secondary airflow stations are of a modular design for easy installation in the

confines of a typical windbox.

This system is currently installed in many cyclone boilers across the country and is a proven means to help balance airflow, reduce NOx and increase plant efficiency. AMC Power offers solutions for all windbox configurations and cyclone types (single damper, split damper, with "blanking plate", etc).

Adobe Acrobat Files:

ACCURATE BURNER AIRFLOW MEASUREMENT FOR NOx BURNERS Paper by AMC Power and DB RILEY.