High

Impedance Traveling-Wave Antenna Preamp

This project is for a differential input shaped-gain preamplifier.

Using a preamp with gain that increases with frequency can be

important to reach the "quiet rural" ITU propagated noise level

target. Aat the same time protecting a receiver from too-strong low

and mid frequency signals and energy is particularly necessary for

broad-band receivers such as SDRs. Shaping the gain between the

radiation resistance of an antenna, particularly a wide-bandwidth one,

may be required to avoid overloading an SDR's ADC at the low frequency

end while still maintaining enough signal and noise levels to maintain

their dominance at the ADC and detector.

This preamp is particularly useful when following a balanced

traveling wave antenna that is being operated over a significant

bandwidth rather than a lower impedance narrower bandwidth and higher

Q 'resonant' antenna. When used with an additional input transformer

to provide transformation from its 100 ohm input impedance to

perhaps 600 ohms and also act as a balun to maintain or provide

symmetry it becomes a good candidate for use with an LoE or Beverage

antenna.

The gain sloping circuit used here is described by Clint, KA7OEI,

and should be read and understood. Because in the end, every receiving

system and location is unique, understanding this makes the path to

tailoring the gain shape for a particular situation easier. The values

used in this kit may be altered at production time by simply selecting

a different JLCPCB C# when a fabricated and assembled PCB is

ordered. Of course, larger changes in the shaping circuit and

the whole design may also be accomplished by using the Hardware Source

code to create an end result even more tailored to meet one's needs.

It's also possible to remove the shaping and obtain a relatively

flat response with higher maximum gain by eliminating or bypassing

shaping components. Maintaining differential input with high

performance amplifiers can still provide low IMD and broad frequency

coverage which may be desirable for other applications.

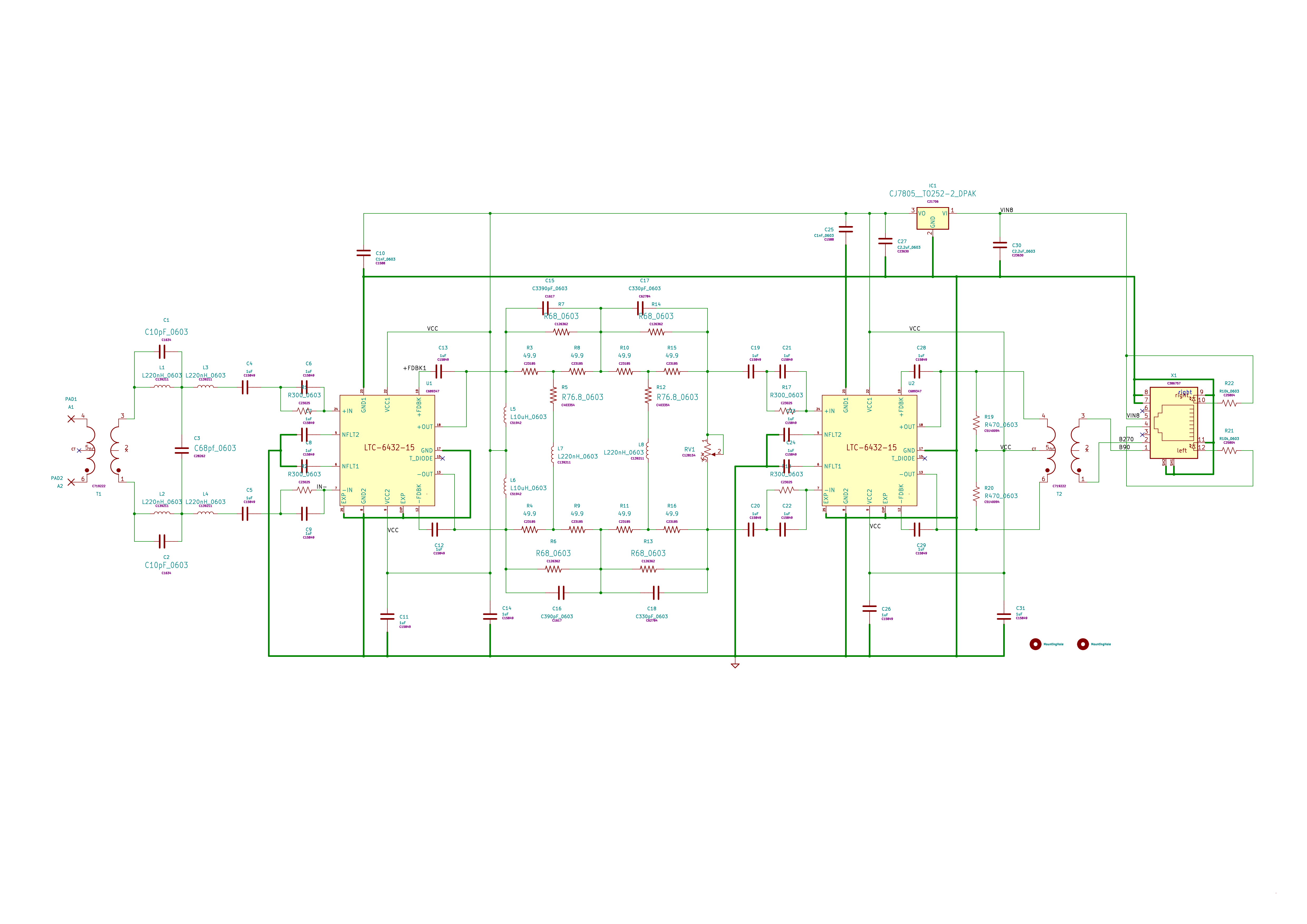

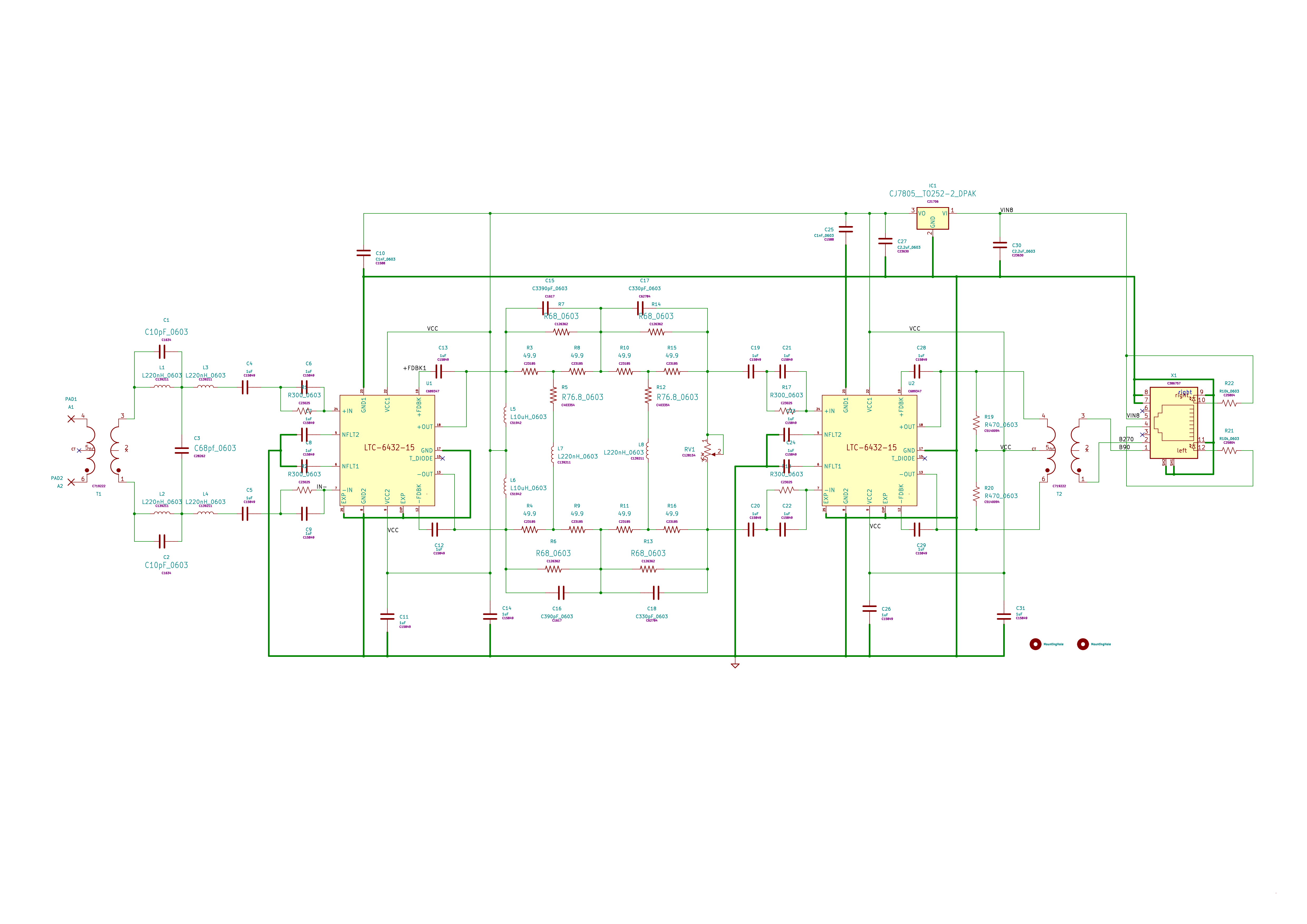

The schematic follows but for

better viewing of the design, download the Kit

file from the Material List

below , unzip it and drop the .sch or .pcb file onto kicanvas

from

a web browser.

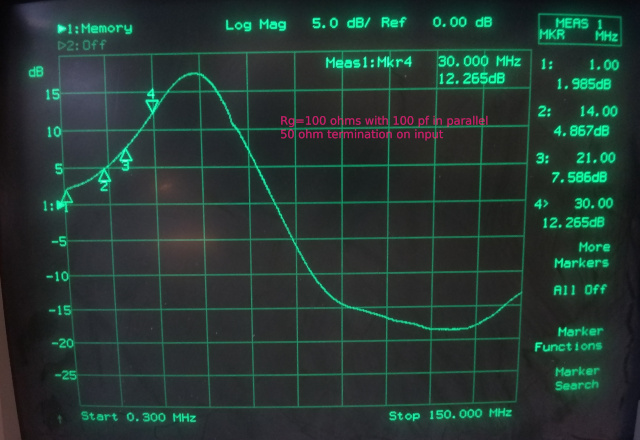

Gain is adjustable, but the shape is shown here:

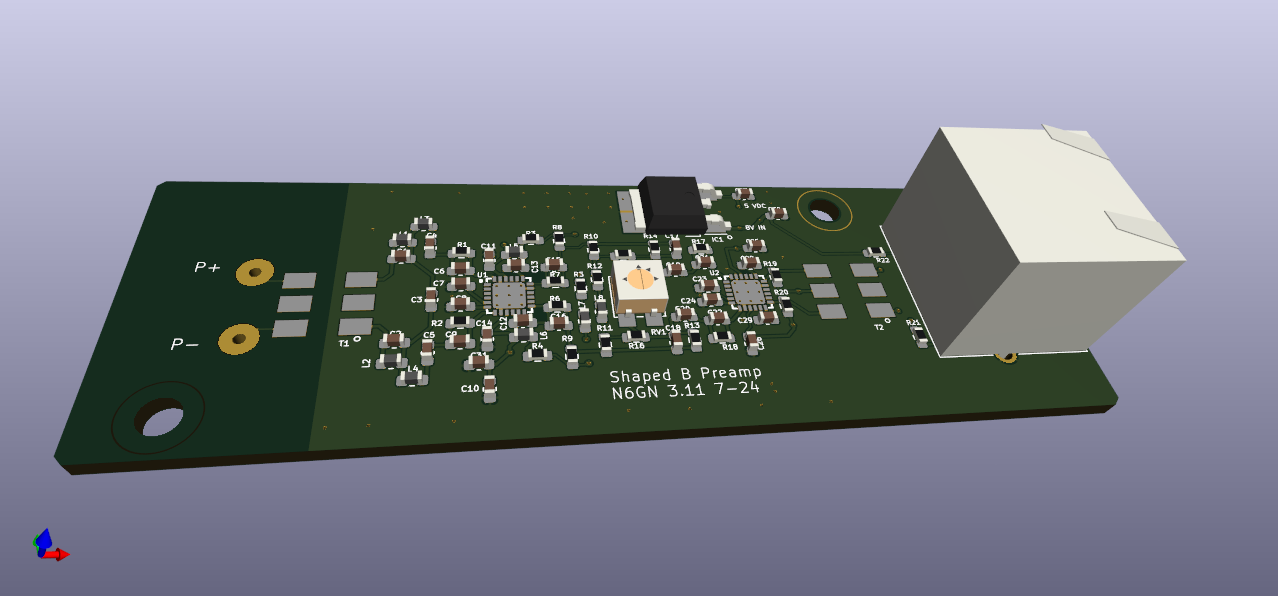

Upon receipt of the assembled Shack and Preamp PCBs from the

manufacturer, simple preliminary testing should be

performed. This should include the absence of shorts on the power

supply input and the output of the 7805 LDO. The board will already have

been flying probe tested at manufacture and physically examined after

all components were soldered but one more test after delivery is good

insurance.

Once there is confidence that everything is OK with the Shack and

PreampB PCBs, 12VDC power can be applied to the Shack PCB and 8V output

voltage measured and the adjustment set for 8V. If possible

it is a good idea to provide the 12VDC from a current limited bench

power supply as extra insurance. Normally PreampB current should

be no more than .5A and PreampB so setting a current limit point

slightly higher than this will ensure that if something has gone wrong,

excessive current can't flow and damage a component.

As given on the material list, the preamps are easily mounted in

common PVC 3/4" electrical T boxes. These accept 3/4" PVC pipe readily

found in hardware stores and used for both electrical and landscape

water systems. Two holes need to be drilled to mount the Preamps.

Place some thermal padding between the bottom of the PCB and the box to

help remove heat from the PCB. PreampB dissipates more than 4 watts so

keeping the PCB relatively cool in hot climates is important. This

technique has worked well even in climates that got quite hot in summer

and cold in winter.

The PVC hardware may not be readily available outside of North

America. For that situation, the user will need to find a way to

accomplish the same goals; an enclosure that can keep the PCB dry, keep

it adequately cool while providing connection for the antenna rods or

wires. Ham ingenuity and a knowledge of suitable locally available

enclosures may be necessary for this. Identifying all possibilites world

wide is well beyond the scope of these instructions.